Adoption View

Data Chain Kit

Vision & Mission

Vision

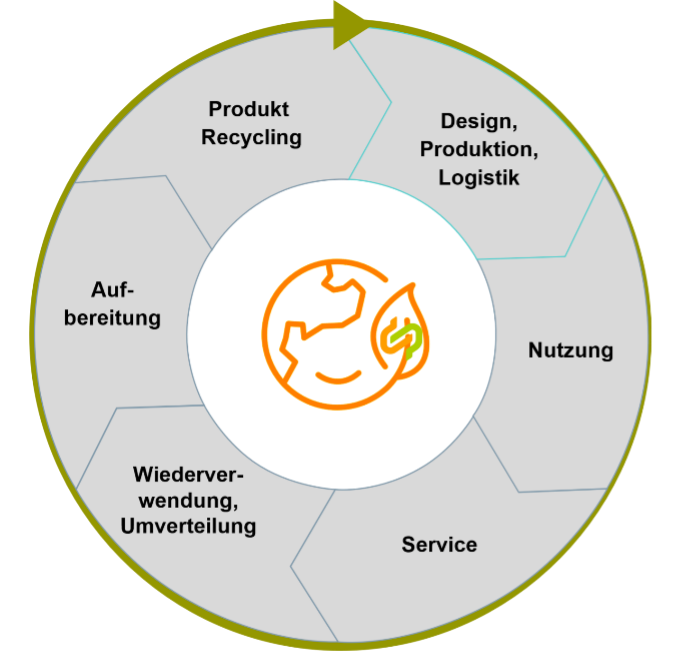

DataChainKit brings valuable data chain information to your use-cases and services through connected data that can help Business Owner and Catena-X participants to be up-to-date and prepared. It's easy to use the DataChainKit with an Open Source Software package, which can easily deployed via HELM or docker-compose. The DataChainKit enables to apply business logic along a distributed data chains, for example aggregation of certificates along the value chain. Also, ad-hoc provisioning of continuous data chains across company boundaries for empowerment of use cases Circular Economy, Traceability, Quality and the European supply chain act.

(#GreenIT#DataSovereignty#Interoperability#ConnectedData)

Mission

The Data Chain KIT provides a reference implementation as functional federated component to handle ad-hoc data chains across n-tiers within the Catena-X network. To realize these data chains, the Data Chain Kit relies on data models of the Traceability use case and provides the federated data chains to customers or applications. Furthermore, the target picture of the IRS includes the enablement of new business areas by means of data chains along the value chain in the automotive industry.

All described specifications in the KIT are based on Catena-X standards and refer to other Catena-X KITs like the Connector KIT (EDC) and Digital Twin Registry to ensure interoperability and data sovereignty according to IDSA and Gaia-X principles.

Customer Journey

With the Data Chain KIT, we support the Catena-X customer journey for our adopters and solutions providers.

There are few steps for your Customer Journey:

- Step 1: Inform yourself & take the decision to become part

- Step 2: Connect your company & teams to Catena-X.

- Step 3: Boost data readiness and governance

- Step 4: Adopt a data driven business process and create instant value

- Step 5: Utilize the full power of collaboration in your business team

Business Value

IRS Iterative

- Application and Service provider can reduce integrate or migrate due to one API specification

- The IRS Iterative API enables an easy interface for complex network tasks

- Potential to scale and optimize network traffic

- The IRS Iterative API is providing one Endpoint to access and collect widely distributed data

- The Data Chain Kit enables interoperability for Data Chains along the value chain to extend

IRS Recursive

- Application and Service provider can reduce integrate or migrate due to one API specification

- The IRS Recursive API enables an easy interface for complex network tasks

- The IRS Recursive API enables different use cases which collect insights over distributed data by not disclosing the supply chain

- The solution enables interoperability with other solutions along the value chain to extend

Use Case

Environmental Social Responsibility (ESR)

Use Case for achieving compliance for Environmental Social Responsibility (ESR) for a component in the supply chain (multi-tier)

In the use case, it was assumed that a company in the supply chain is considered "compliant" if that company can show the ISO 14001 certificate. Presenting means that either the company itself provides it as a data provider or deposits it in a certificate repository with a service provider.

The benefit of the solution is to obtain an automated overview of the supply chain's compliance and to be able to check it again and again on a cyclical basis. The companies in the supply chain are not disclosed, which follows the Catena-X specifications.

The decentralized implementation at Catena-X "traverses" from the OEM to the direct supplier and from the direct supplier to its next supplier and thus through the supply chain for a specific component. Each partner determines its direct supplier automatically via the parts list stored by it in Catena-X's Item Relationship Service (IRS).

Aggregated information on the compliance of the upstream suppliers is returned to the OEM via each stage of the supply chain. From this, the OEM can finally read how many companies are compliant and how many are non-compliant in its supply chain for the component.

The names of the suppliers further down the supply chain are not disclosed to follow the Catena-X data sovereignty principle one-up-one-down, but each intermediate level sees which of the direct suppliers are non-compliant and can act, so that perspectively the whole supply chain is assessed as compliant.

Environmental and Social Standards (ESS) Top-Down

With the entry into force of the German Supply Chain Due Diligence Act as from January 1st, 2023, German companies are obliged to implement the corresponding requirements of this law. In addition, the following European directives on this subject have also been adopted: EU regulation 2018/858. This regulation is legally binding to all EU member states.

This use-case facilitates the IRS Recursive approach and enables data providers to provide the BoM as planned aspect models via the Catena-X defined solution stack (i.e. EDC). The BoM as planned aspect models consists of three aspect models:

- SingleLevelBomAsPlanned - The single-level bill of material (BoM) represents one sub-level of an assembly and does not include any lower-level subassemblies. In the As-Planned lifecycle state all variants are covered ("120% BoM"). If multiple versions of child parts exist that can be assembled into the same parent part, all versions of the child part are included in the BoM. If there are multiple suppliers for the same child part, each supplier has an entry for their child part in the BoM.

- PartAsPlanned - representation of an item in the Catena-X Bill of Material (BOM) in As-Planned lifecycle status in a specific version. This also includes information about the validityPeriod - the period of time during which the Part is offered by the manufacturer and can be purchased by customers.

- PartSiteInformationAsPlanned - Site related information for a given as planned item. A site is a delimited geographical area where a legal entity does business. In the "as planned" lifecycle context all potentially related sites are listed including all sites where e.g. production of this part (type) is planned.

Step 0: Process initiation

The process is initiated by an ESS incident, that is received by (or created within) the inquiring company. This ESS incident acts as the root incident for the overall process. The incident contains a company name (incl. address) and a valid BPN exists for that company. The BPN (a BPNL or BPNS) can be looked up in BPDM.

Step 1: Check direct suppliers

The inquiring company checks, if the company of the incident is a direct supplier of them. In order to perform this check, the following data must be available in the inquiring company:

- Full list of direct suppliers

- Full list of parts supplied by those direct suppliers

In case the company of the incident is a direct supplier of the inquiring company, the process ends. In case the company of the incident is not a direct supplier of the inquiring company, Step 2 is executed.

Step 2: Forward Incident

The incident is forwarded to all direct suppliers. Each direct supplier is sent a "personalized" request to evaluate, if the inquiring company is impacted by the incident. The incident is enhanced with additional data by the inquiring company:

- List of parts, that are supplied to the inquiring company by their direct supplier.

Each direct supplier executes Step 1.

Step 3: Gather Responses

The inquiring company collects the (asynchronous) responses. The response of each direct supplier may contain the following results:

- YES → The company of the incident was found in the supply chain of the given list of parts. In this case, the result also contains the BPN of the direct supplier where the incident occurred alongside the number of hops (i.e. how many levels down the chain) to where the incident occurred

- NO → The company of the incident was not found in the supply chain of the given list of parts

- UNKNOWN → The query timed out or some other error occurred

In case at least one "YES" is received, the process step 3 ends

Environmental and Social Standards (ESS) Bottom-Up

The occasion related traceability helps stakeholders to identify if a company that is detected for social or environmental misbehavior is part of its own supply chain. In case of a hit, the inquiring company and the originator company will be informed by the response, and therefore if the specific company has to start investigations.

Similar to the ESS use-case Top-Down, ESS Bottom-Up focuses on notifying customers about incidents in the supply chain. The difference to Top-Down is that the Bottom-Up approach only investigates on one level and does not send any notifications. To achieve this goal, IRS uses these aspect models:

- SingleLevelUsageAsPlanned - The aspect provides the information in which parent part(s)/product(s) the given item is assembled in. This could be a 1:1 relationship in terms of e.g. a brake component or 1:n for e.g. coatings. The given item as well as the parent item must refer to an object from as-planned lifecycle phase. If multiple versions of parent parts exist that the child part can be assembled into, all versions of the parent part are included in the usage list.

- PartAsPlanned - representation of an item in the Catena-X Bill of Material (BOM) in As-Planned lifecycle status in a specific version. This also includes information about the validityPeriod - the period of time during which the Part is offered by the manufacturer and can be purchased by customers.

- PartSiteInformationAsPlanned - Site related information for a given "as planned" item. A site is a delimited geographical area where a legal entity does business. In the "as planned" lifecycle context all potentially related sites are listed including all sites where e.g. production of this part (type) is planned.

For the originator company, IRS validates whether the requested BPNS is part of their PartSiteInformationAsPlanned and whether the provided validityTimestamp is within the validityPeriod of PartAsPlanned. If this is the case, IRS will then collect all the BPNLs of the direct customer and return the affected parts in the following structure for an incident company to handle further incident management:

{

"customers": [

{

"businessPartnerNumberLegalEntity": "<bpnl>",

"customerParts": [

{

"globalAssetId": "<globalAssetId>",

"sites": [

{

<BPNS>

}

]

},

...

]

}

]

}

Data Integrity Layer (DIL) - Spike

The use-case Data Integrity Layer is an additional Layer in IRS processing. It aims to verify integrity along the data chain by introducing a new aspect model: DataIntegrity. This model contains hashes and signatures of semantic models in a parent - child structure, similar to SingleLevelBomAsBuilt:

{

"catenaXId": "urn:uuid:123",

"childParts": [

{

"catenaXId": "urn:uuid:456",

"references": [

{

"semanticModelUrn": "urn:bamm:io.catenax.data_integrity:1.0.0#DataIntegrity",

"hash": "5a4cc1c6817b0045b26d3e842482753b5ad1cf20fbedebed2ee3c09936800821",

"signature": "e71196ddd321cc0f87cca372c304d74b9e741d8a5a3ddd5b953877b1f65a5206815d20f53bb51cf3d7725ed14fb5e18bd7b65e0ba9ef0e2f0cb44b5d5fc42e4197ce004ce4d0369e15c0429c7097099d46ce8640ff7197ac57f8045d3db996df1deaf8e7f01b447118d62876d2cd44484d2e2c49fac4a47c8a6ea9177142d8efdc032fd5638968dcd8982349b65cc6f75409dccc2386aa5e76c397d77e54e0fe4add1c870af5eab754c911595e8dc4b6e33643d15b95c2f8b62524702e30bf49736063e71761f6382aca8b46fffbd529495bba075e29fc540cd0a9b11c349512ddd97c371b9eb7e56196b5236f31290912f2f282786042a6a81017030a6d82eb"

},

{

"semanticModelUrn": "urn:bamm:io.catenax.serial_part:1.0.1#SerialPart",

"hash": "823dd4d758f2aafd5cf63de1144b178118cfe97388678d9b42eabe65a7e66e55",

"signature": "4ac7a5feb1724bbf5e6f9ba8ed55f09133185b9f9c49b627f6bc7f36b49e42f4dcfecd19bb64ad0bdc93742bab5add7a45f67ff7a2603f93e62f2b2bd4ed606b0d637f075df73b5aef91e8f20128dd55e62cce2f059beb59723927835e6e108c84170d7ca03a11fc65a9d57d618156c69fde6112955e53dca04bd0f860b75477eb7b58ee10ab8e5d3bcaacdfa1b6ba0f86e6d2518154642c1da8a42397221a556cfc536614298afeeaf5098c18f5aaf260bf78bfea30e066316819d0f442491fdf4cdc10929605ebefef05c5a503b62b8788d6bb9c76b8a9108987beca19cb5eae50bd83a5f29e241689f1450d4c06a7524955f4fbf6c4d773ef3a94e4a3a1a8"

},

{

"semanticModelUrn": "urn:bamm:io.catenax.single_level_bom_as_built:1.0.0#SingleLevelBomAsBuilt",

"hash": "e2efea25b47bec2b5ce2a65b4785172240d97acfbd7f223ae009f9686a155e16",

"signature": "a0b344cd9fc3c5d51738a5f1b76ba079319ea9d270f181b0e691ff7a6bbc6eaab3955c324d9b7b8db679473408961cb06826532bb4bd54321d9e04539f6bd520def9b648e3a06a4ee035f4d961212a46404ac512ea64d72224af474ebe004ae87ec121078db994e7750324e7a2de66667512b3b2c0e60ba8c1391dcfcfe57f21b51256fc1a794cdace47a70561136328a7b8fce8539533c971d6ef29ea57c04fb6f87e873c0b66ca21c70f8689696b42bec47c718d9145f2de8bea38d9dc1718322ddc6014b6d781db846446c0dcb4ce3c6dda8e018be2732b32f414fd074dfadf87fa605ca57598095df7d139432015a0ba6a125089f835ee0af4db8a733074"

}

]

},

...

]

}

Based on the DataIntegrity aspect IRS can compare the data received by a data provider with the given hash and verify that the data was not altered or manipulated after initial provision.

Success Stories

Circularity Dashboard Success Story

Due to the large number of producers and consumers, however, the implementation of the circular economy is challenging: Information on the individual lifecycles is mostly only available locally and therefore does not provide any meaningful assessment of reuse, recycling or remanufacturing.

Therefore, the circularity dashboard, gives the user information about materials of the product and of all their composites. This is only possible, if participants of the supply chain, the direct manufactures of the composites of a vehicle are sharing information about the materials used. The ability to access provided data in the Catena-X network could be done in two different ways. Way one is to handle each request separately, or use the IRS, which manages the retrieval of digital twins, checks and validates the results against the semantics and provides an easy-to-use API to interact with the decentral stored data. In the SAP Industry Network for Automotive, circularity cockpit API specification and IRS implementation are serving as a reference. Thus, we were able to develop IRS functionality to best fit the SAP tech stack, which we decided to use for the circularity cockpit. This enables us, to have a controlled access to distributed data in an interoperable setup to access data chains. To abstract the data consumption layer brings benefits in stability and resiliency to our application, because we could easily change to different providers or services of a IRS implementation.

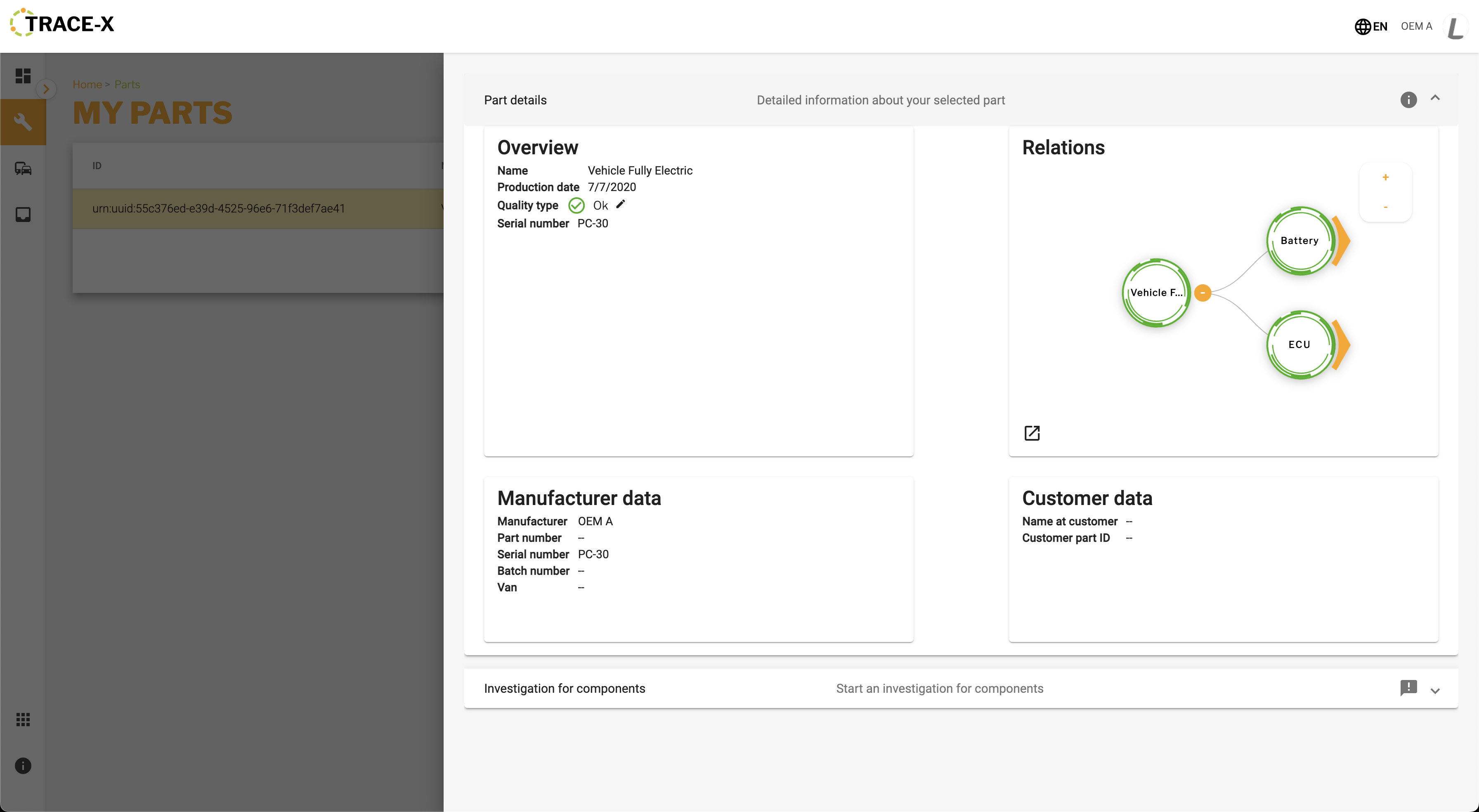

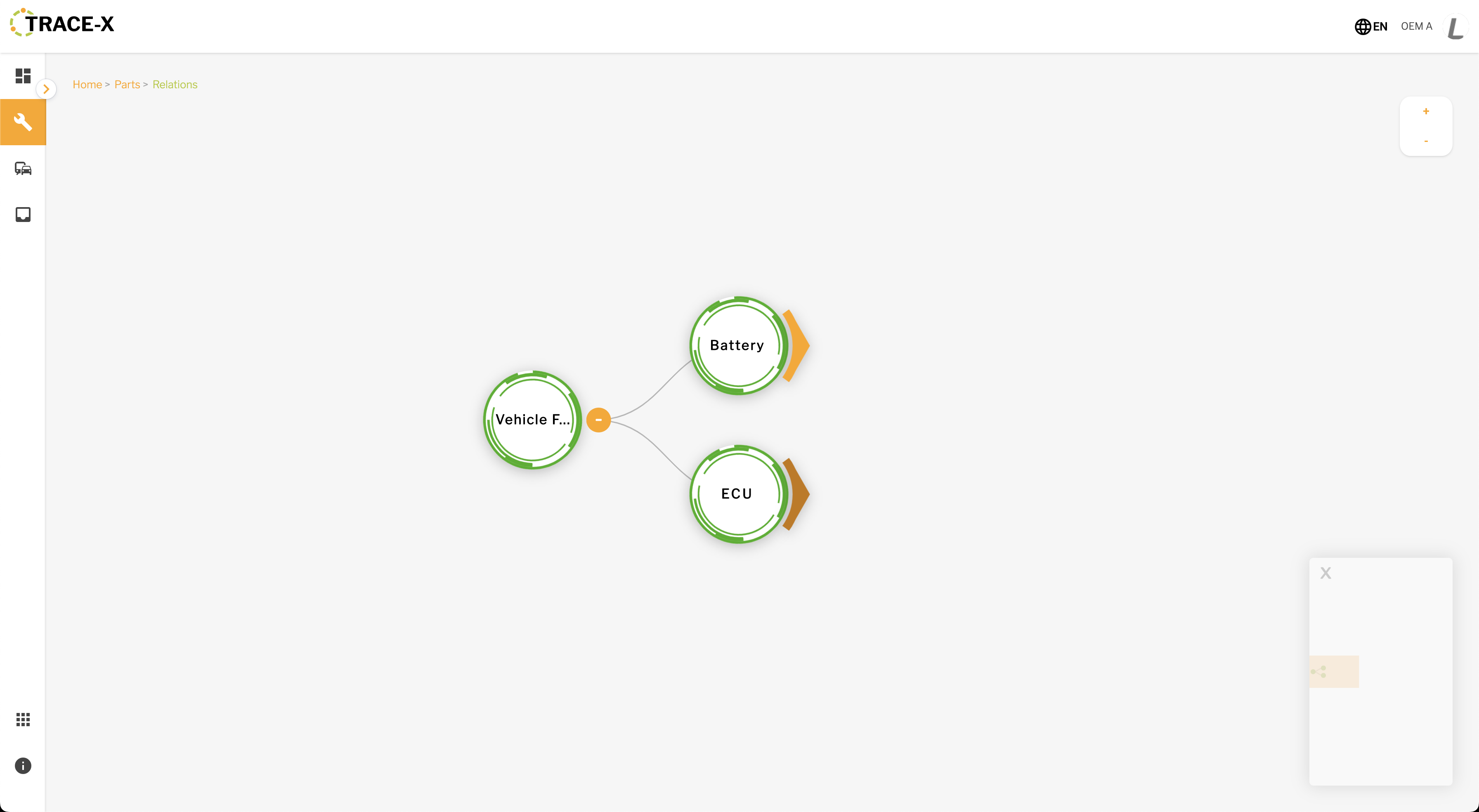

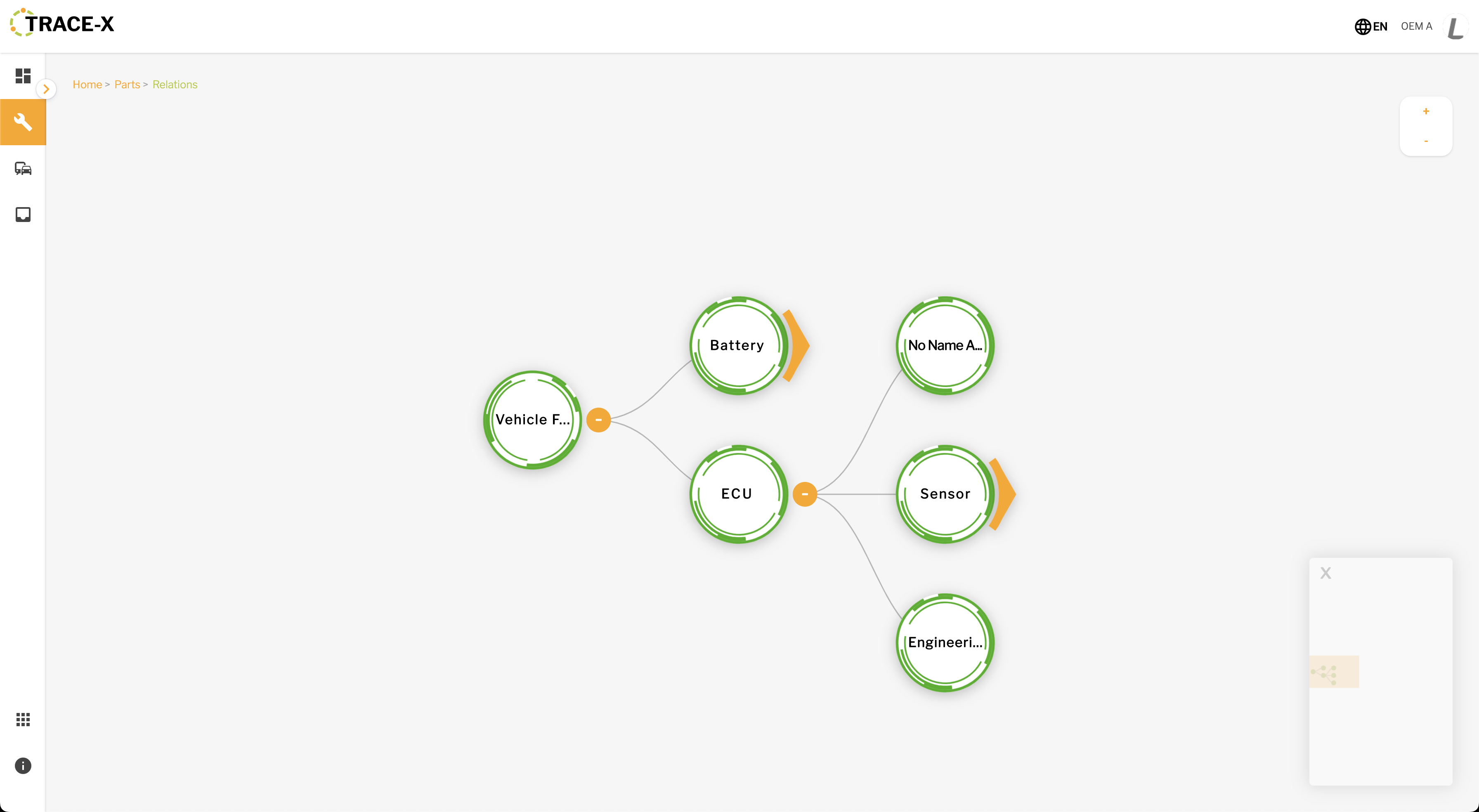

Trace-X Success Story

The Open-Source Traceability application is developed within the Catena-X project and enables all companies to participate in Parts Traceability. Trace-X offers capabilities to ingest data for serialized parts and batches as well as their child components. Within CX, we strive to establish a standardized, data-sovereign and interoperable exchange of traceability data along the value creation chain.

The application gives an overview of the supplier network and the supply chain. A high level of transparency across the supplier network enables faster intervention based on recorded events in the supply chain. Additionally, automated massages regarding Quality related incidents. All this saves' costs by seamlessly tracking parts as well as creates trust through clearly defined and secure data access by the companies and persons involved in the process.

Applying and using the Item Relationship Service had the following benefits:

- With the decision using the IRS we could speed our development of Trace-X throughout the scope of their helm charts including a running service with test data. That alone was very beneficial to have a stable environment with data

- The IRS fulfills a high level of quality in code which provides a reliable service

- The deployment via helm charts has been built so that it can fit in existing architecture components throughout configuration like the Digital Twin Registry, the EDC, Semantic Hub, Keycloak and others. This enabled Trace-X to configure the Service smoothly into the architecture of the application

- The IRS abstracts the communication with partners along the supply chain, that makes it easy to build business processes on that. It abstracts a technical level to a logical level to enhance the speed of implementation of a Software Provider

- The IRS with the standardized API provides a data interoperability level on data chains

- The Team behind the IRS is fast in implementing and adapting new features

Logic & Schema

Building Block Architecture Overview

IRS Components

| Components | Description |

|---|---|

| IRS | The IRS builds a digital representation of a product (digital twin) and the relationships of items the product consists of in a hierarchical structure. The result is an item graph in which each node represents a digital item of the product - this graph is called "Item Graph". |

| IRS API | The IRS API is the Interface over which the Data Consumer is communicating. |

| IrsController | The IrsController provides a REST Interface for retrieving IRS processed data and job details of the current item graph retrieval process. |

| IrsItemGraphQueryService | The IrsItemGraphQueryService implements the REST Interface of the IrsController. |

| JobOrchestrator | The JobOrchestrator is a component which manages (start, end, cancel, resume) the jobs which execute the item graph retrieval process. |

| RecursiveJobHandler | The RecursiveJobHandler handles the job execution recursively until a given abort criteria is reached or the complete item graph is build. |

| TransferProcessManager | The TransferProcessManager handles the outgoing requests to the various data services. |

| Policy Store | The Policy Store provides an Interface for getting, adding and deleting accepted IRS EDC policies. These policies will be used to validate EDC contract offers. |

| BlobStore | The BlobStore is the database where the relationships and tombstones are stored for a requested item. |

| JobStore | The JobStore is the database where the jobs with the information about the requested item are stored. |

| Digital Twin Registry Client | The Digital Twin Registry Client is the interface to the Digital Twin Registry. It provides an interface for the Asset Administration Shells. |

| Decentralized Digital Twin Client | In a decentralized network, the Digital Twin Client connects to the EDC which then proxies the requests to the digital twin registry on provider side. |

| EDC Client | The EDC Client is used to communicate with the EDC network, negotiate contracts and retrieve submodel data. |

Catena-X Core Services

| Subsystem | Description |

|---|---|

| Digital Twin Registry | The Digital Twin Registry acts as an address book for Digital Twins. Data Providers register their Digital Twins in the Digital Twin Registry. Data consumers query the Digital Twin Registry to find Digital Twins and interact with them further. A Digital Twin contains endpoint references to submodel endpoints. Calling a submodel endpoint returns data compliant to a semantic model. A semantic model describes the data that a Submodel endpoint returns. Repository of the Digital Twin Registry. |

| Eclipse Dataspace Connector (EDC) | The Eclipse Dataspace Connector provides a framework for sovereign, inter-organizational data exchange. It will implement the International Data Spaces standard (IDS) as well as relevant protocols associated with GAIA-X. The connector is designed in an extensible way in order to support alternative protocols and integrate in various ecosystems. Repository of the Catena-X specific EDC. |

| Discovery Service | The Discovery Service interface is a CX network public available endpoint which can get used to retrieve EDC Discovery Service or BPN Discovery Services via a given type. |

| Portal | The Catena-X Portal and Marketplace is the heart of Catena-X and the entry point for all activities in the automotive network/value chain. Every user of the automotive value chain, no matter if it is a consumer, app provider, IT administrator or IT support will connect via the portal to the value bringing services. The whole eco-system on the automotive value chain is connected at one place. |

| EDC Discovery Finder | The EDC dataspace discovery interface is a CX network public available endpoint which can get used to retrieve edc endpoints and the related BPNs, as well as search for endpoints via the BPN |

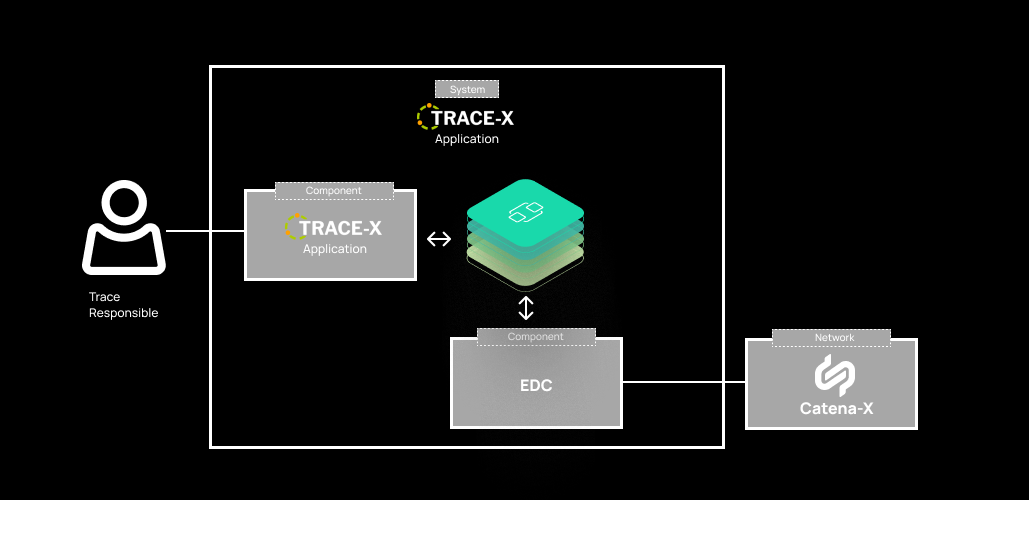

Business Process

The DataChainKit acts as a middleware between consumers and manufacturers. This section describes the Business Process of DataChainKit. Who are its users, and with which other systems does it interact with.

Consumer

The DataChainKit by IRS API is the essential component of the business app Trace-X FOSS to be able to build data chains in upwards and downwards direction for BOM lifecycles asBuilt and asPlanned. The DataChainKit by IRS API is being consumed by the dismantler dashboard and other parties which are part of the Catena-X network. They need to provide valid credentials issued by the Catena-X Portal/IdP. Additionally, they must provide a base global asset identifier to retrieve information for as well as configuration details for the view on that information. The DataChainKit by IRS API is the essential component of the business app Trace-X FOSS to be able to build data chains in upwards and downwards direction for BOM lifecycles asBuilt and asPlanned. The DataChainKit by IRS API is being consumed by the dismantler dashboard and other parties which are part of the Catena-X network. They need to provide valid credentials issued by the Catena-X Portal/IdP. Additionally, they must provide a base global asset identifier to retrieve information for as well as configuration details for the view on that information.

Catena-X network

The IRS retrieves data from the Catena-X network (using the necessary infrastructure, see Technical Context), aggregates it and provides it back to the consumers. This connection is mandatory. If the Catena-X services are unavailable, the IRS cannot perform any work.

As of now, the IRS uses technical user credentials provided by the portal to gather the required data. This might be changed to use the consumer credentials in the future.

Standards

Our relevant standards can be downloaded from the official Catena-X Standard Library

Why Data Chain Kit

What is in for you to use the Data Chain Kit. On what is it built on.

IRS Iterative

The IRS iterative iterates through the different digital twin aspects, which are representing a relationship. For Release 3.2 this is the SingleLevelBOMasBuilt aspect, which connects serialized parts. This service can access the digital twins for which an EDC policy and a data contract exists. In this case the consumer needs a contract which each participant of the data chain.

The following general conditions apply:

- Access control through policies and contracts is done by the EDC

- Direct data exchange between supply-chain partners

- Catena-X partners of the accessible value chain are known to the data-consumer

IRS Recursive

The IRS recursive works different as the IRS iterative. It does not consume the digital twins of the partners in the supply chain in a direct way, it triggers the IRS of a partner to start an IRS job to retrieve data of the sub-partners. This is done to keep the structure below intransparent to the value chain above, even though it is still possible to aggregate results; pass information along the value chain.

The following general conditions apply:

- The IRS recursive is for use-cases, which want to apply business logic with data along the value chain. For example, to summarize, or check for existence of values or certificates.

- Each participant has the possibility to check their values, before passing them to next in line

- Access control through policies and contracts is done by the EDC

- Direct data exchange between supply-chain partners

- Business logic is being applied with an extension concept

The recursive approach is based on a decentralized network in which only the next level of a relationship between two companies (one level down approach) is known. (Relationship: Customer - Supplier)

- Company OEM initiate request using a consumer application.

- Company (supplier) is identified on the next lower level - then a message is sent to the IRS instance of this supplier.

- After receiving the message on supplier level, the IRS determines the suppliers on the next lower level and also sends a message to the IRS instances of the suppliers.

- This is repeated until a leaf node (a company has no more suppliers or the company is not part of the C-X network) is reached.

- In this case the leaf node is responding with a message to the customer company.

- The IRS on customer company level receives and aggregates the messages from all requested suppliers and responds again to the customer until OEM level is reached.

- OEM shows result of recursive investigation according to the given use case in consumer application.

NOTICE

This work is licensed under the CC-BY-4.0.

- SPDX-License-Identifier: CC-BY-4.0

- SPDX-FileCopyrightText: 2021, 2023 Bayerische Motoren Werke Aktiengesellschaft (BMW AG)

- SPDX-FileCopyrightText: 2022, 2023 BOSCH AG

- SPDX-FileCopyrightText: 2021, 2022 ZF Friedrichshafen AG

- SPDX-FileCopyrightText: 2022 ISTOS GmbH

- SPDX-FileCopyrightText: 2021, 2023 Contributors to the Eclipse Foundation

- Source URL: https://github.com/eclipse-tractusx/item-relationship-service